Categories

- Conical Spring Mechanical Seals

- Parallel Spring mechanical Seals

- Multiple Spring mechanical Seals

- Wave Spring Mechanical Seal

- Metal Bellows mechanical seal

- Cartridge mechanical seal

- PTFE-Bellows Seal

- Parallel Spring Diaphragm Mechanical Seal

- Elastomeric Bellows mechanical seal

- Brand Pump Seals-General Industrial

- Brand Pump Seals-Food and Beverage Industry

- Stationary seat Type

Detail Information

Features

Wave Spring

Bi-dire ctional

EN 12756 Standard

Equivalent to WO7DMU

Recommended Applications

Paper and textile printing industry, petrochemical industry and sewage treatment industry

Low solids content or viscous media

Sewage pumps, chemical pumps, screw pumps, Gear wheel feed pumps and multistage pumps

Other Rotating Equipment.

Operating range

Shaft diameter: d1=14...100mm

Pressure: p=0...1.6Mpa(232psi)

Temperature: t = -40 °C ...220 °C(-40°F to 428°F)

Sliding velocity: Vg≤20m/s(65.6ft/s)

Notes: The range of preesure,temperature and sliding velocity is depend on seals combination material

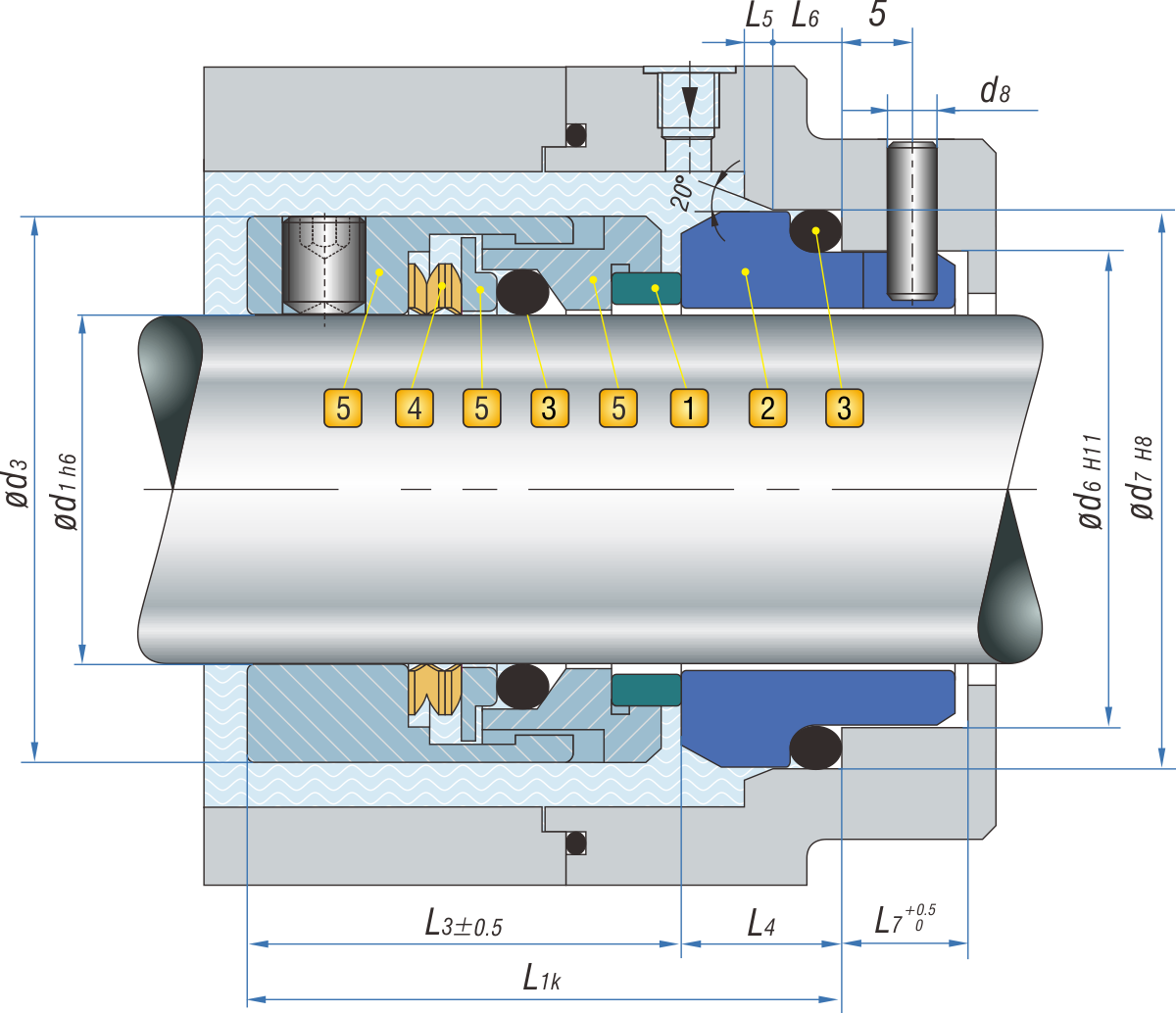

Product Structure

Combination Materials

1.Rotary Face

Reaction Bonded Sic RBSlC O

Sintered Silicon Carbide SSlC O1

Tungsten Carbide.Ni-binder W

Cr-Steel (Solid) E

2.Stationary Seat

Carbon graphite, resin impreg Ak

Carbon graphite,antimonyimpreg AD

Reaction Bonded Sic RBSlC O

Sintered Silicon Carbide SSlC O1

Tungsten Carbide.Ni-binder W

3.Auxiliary Seal

Elastomers 0-ring

Fluorocarbon Rubber FKM V

Etylene Propylene RubberEPDM E

KPerfluorocarbon Rubber FFKM K

Encapsulated 0-ring

FEP Jacketed FKM M1

4.Spring

GrNi-Steel (AlS1304) F

GrNiMo-Steel (AlS1316) G

5.Metal Parts

GrNi-Steel (AlS1304) F

GrNiMo-Steel (AlS1316) G

Review

- Loading...

Please send your message to us

If you have any questions please ask here. TNG® needs the contact information you provide to us to contact you about our products and services. For information on our privacy practices and commitment to protecting your privacy.

- Mobile Phone

- *Title

- *Content

Do you need any further information?

Please send your message to us

If you have any questions please ask here. TNG® needs the contact information you provide to us to contact you about our products and services. For information on our privacy practices and commitment to protecting your privacy.

- Mobile Phone

- *Title

- *Content